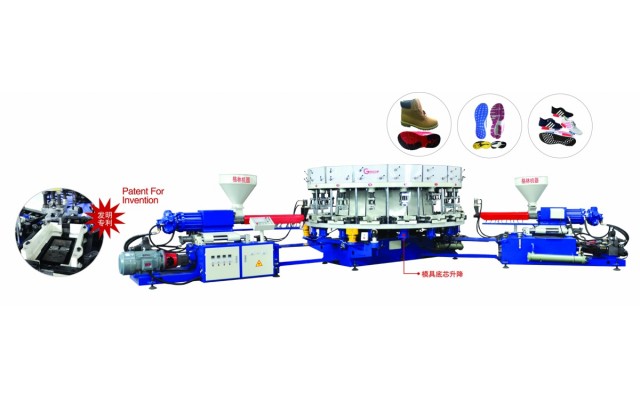

1.PLC controlled,preplasticized by hydraulic motor, driven by full hydraulic pressure,and cycled automatically.

2.High plastifying capacity,the plastifying temperature can be controlled automatically by preselection.

3.It adopts 16X2 points measuring and the injection volume can be chosen according to the requirements of the moulds at each working position.

4.The function of empty mould selection has been provided.

5.The round table is indexed by a frequency converter

6.Parallel mould plate closing mechanism is adopted, which linked with a toggle system operated by a single cylinder.

7.The machine is equipped with two time pressure injection system and the cramp pressing and mould closing order selecting function.

8.The round table indexes smoothly and it's movement can easily be adjusted.

9.The round table rotation, plasticizing and oil supply for the injection are controlled independently.

10.There are many working positions, the time for setting is long enough, and guarantees the setting quality of shoe soles.

|

Model |

Unit | Specification | ||

|---|---|---|---|---|

|

GLP-16 |

GL2P-20D |

GL2P-24D |

||

| Number of stations | PCS | 16 | 16 | 24 |

| Screw diameter | mm | 75 | 70/60 | 70/60 |

| Screw speed | r/min | 0-160 | 0-160 | 0-160 |

| Screw length to diameter ratio | 18:1 | 18:1 | 18:1 | |

| Maximum injection volume | cm3 | 580 | 580/310 | 580/310 |

| Plasticizing ability | g/s | 40 | 40 | 40 |

| Injection pressure | kg/cm2 | 100 | 100 | 100 |

| Disc system pressure | kg/cm2 | 50 | 50 | 50 |

| Mold mode | Parallel | Parallel | Parallel | |

| Pick up the itinerary | mm | 80 | 80 |

80 |

| Shoe height | mm | 210-260 | 210-260 | 210-260 |

| Frame size |

L(mm) K(mm) H(mm) |

380 180 80 |

380 180 80 |

380 180 80 |

| Installed power | KW | 20.5 | 31.5 | 31.5 |

| Overall dimensions |

L(mm) K(mm) H(mm) |

6135 3350 1955 |

8550 5500 1955 |

7950 7750 1900 |

| Total Weight | kg | 11500 | 14800 |

19000 |

| Mould up and down trip | mm | 80 | 80 | 80 |